High Power Opto Sensors for Carwash Applications

|

The environment in car wash applications: wet floors, reflecting walls, water spray. With over 30 years of know-how, special opto sensors Pantron are optimized for these conditions. These sensors are as sensitive to detect a convex windscreen, and as strong to detect the wheels at simultaneous undercar wash. |

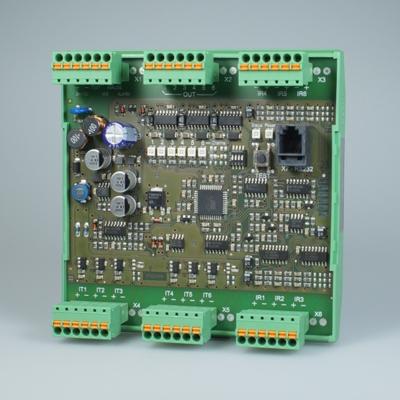

The ICL-2000 is a dual-channel opto sensor which is specially tailored to operate in car washes. This device replaces two single-channel opto sensors with the advantage of no mutual interaction between each single channel. Four level settings are used for different installation situations in a car wash. The automatic operating mode provides a secure functionality that adjusts to external interferences, deterioration and misalignment of the sensors. The device has semiconductor outputs. |

The ICL-6000 is a six-channel opto sensor which is specially tailored to operate in car washes. This device replaces six single-channel opto sensors with the advantage of no mutual interaction between each single channel. Four level settings are used for different installation situations in a car wash. The automatic operating mode provides a secure functionality that adjusts to external interferences, deterioration and misalignment of the sensors. The device has semiconductor outputs. |

The ICL-8000 is a eight-channel opto sensor which is specially tailored to operate in car washes. This device replaces eight single-channel opto sensors with the advantage of no mutual interaction between each single channel. Four level settings are used for different installation situations in a car wash. The automatic operating mode provides a secure functionality that adjusts to external interferences, deterioration and misalignment of the sensors. The device has semiconductor outputs. |

An amplifier that is specially tailored to operate in car washes (washing gantries and car wash plants). The special programming of this device enables perfect operation in the difficult environmental conditions that exist in the car wash industry. In particular, there are problems with wet and specular walls and floors, reflective vehicle roofs or sudden spray. On one hand, the device is sensitive enough to detect curved windshields and on the other, it is powerful enough for wheel detection during simultaneous high pressure under body and side washing. |

An amplifier that is special tailored to operate in car washes (washing gantries). It differs from other light barriers of the ISG series in 4-fold frequency switching for better decoupling of the detection ranges if the mounting is very close. Furthermore it differs in an increase of firm capacity during high setting. The light/dark switching is realised via a bond bridge in DIN-socket. |

Single channel system with automatic operation. Four levels for individual range setting. four frequency settings allow close mounting of adjacent beams. Sensor alignment information and diagnostics are available at the touch of a button. LED indicators for output signal and gain control. Alarm indicator and alarm output. Electronic output stage (PhotoMOS). Test input for functional test by external test equipment. |

Two channel multiplexed system with automatic operation. Four levels for individual range setting. Sensor alignment information and diagnostics are available at the touch of a button. LED indicators for output signal and gain control. Alarm indicator and alarm output. Electronic output stage (PhotoMOS). Test input for functional test by external test equipment. |

Four-channel multiplexed system with manual and automatic operation modes. This system is extremely dirt resistant and specially tailored to operate in car washes. Menu-driven setup allows individual parameter settings for each channel: |

Eight-channel multiplexed system with manual and automatic operation modes. This system is extremely dirt resistant and specially tailored to operate in car washes. Menu-driven setup allows individual parameter settings for each channel: |