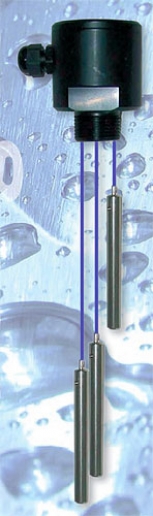

The probe relay (Ex) SRA-100-U0 works in conjunction with conductive probes, as a level limit switch or control in conductive liquids such as water, alkalis and acids. A functional extra-low voltage according to VDE 0100 Part 410 of approx. 9V is applied to the electrodes, which means that touching the probes is completely harmless.

As soon as the electrically conductive filling material forms a connection between ground and e.g. the maximum electrode, a small alternating current flows, which is converted into a relay output in the evaluation electronics.

In the case of metallic containers, the container wall can be used as the mass, or an electrode in the case of non-metallic containers. The use of alternating voltage prevents corrosion on the probe rods and electrolytic decomposition of the product. The device can work with relay locking or minimum and maximum switching points, as well as a double limit level indicator with two separate outputs.

This enables a variety of measurement tasks, such as overflow, dry run protection, two-point control, moisture detection, etc. to be implemented. The sensitivity to the conductivity of the liquid can be adjusted via a coarse and fine adjustment. With an adjustable switching delay of up to approx. 8 seconds, any wave movements in the container are masked out.

As further special features, the probe relay (Ex) SRA-100-U0 offers line break monitoring with an alarm relay, a wide-range supply of 20 … 253V AC / DC and the option of using the electrodes in Ex areas (up to Zone 0).